description

1、 machine introduction:

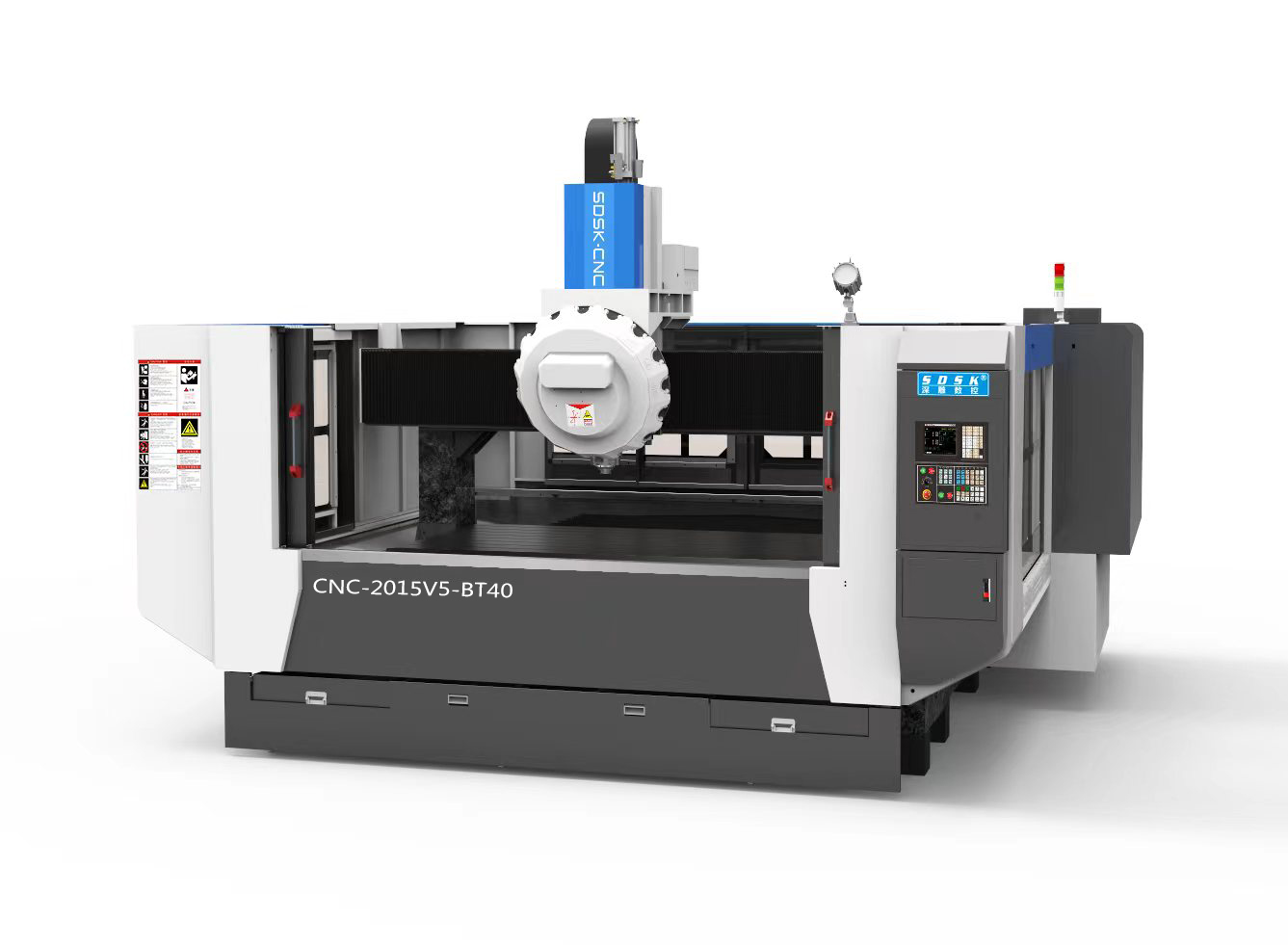

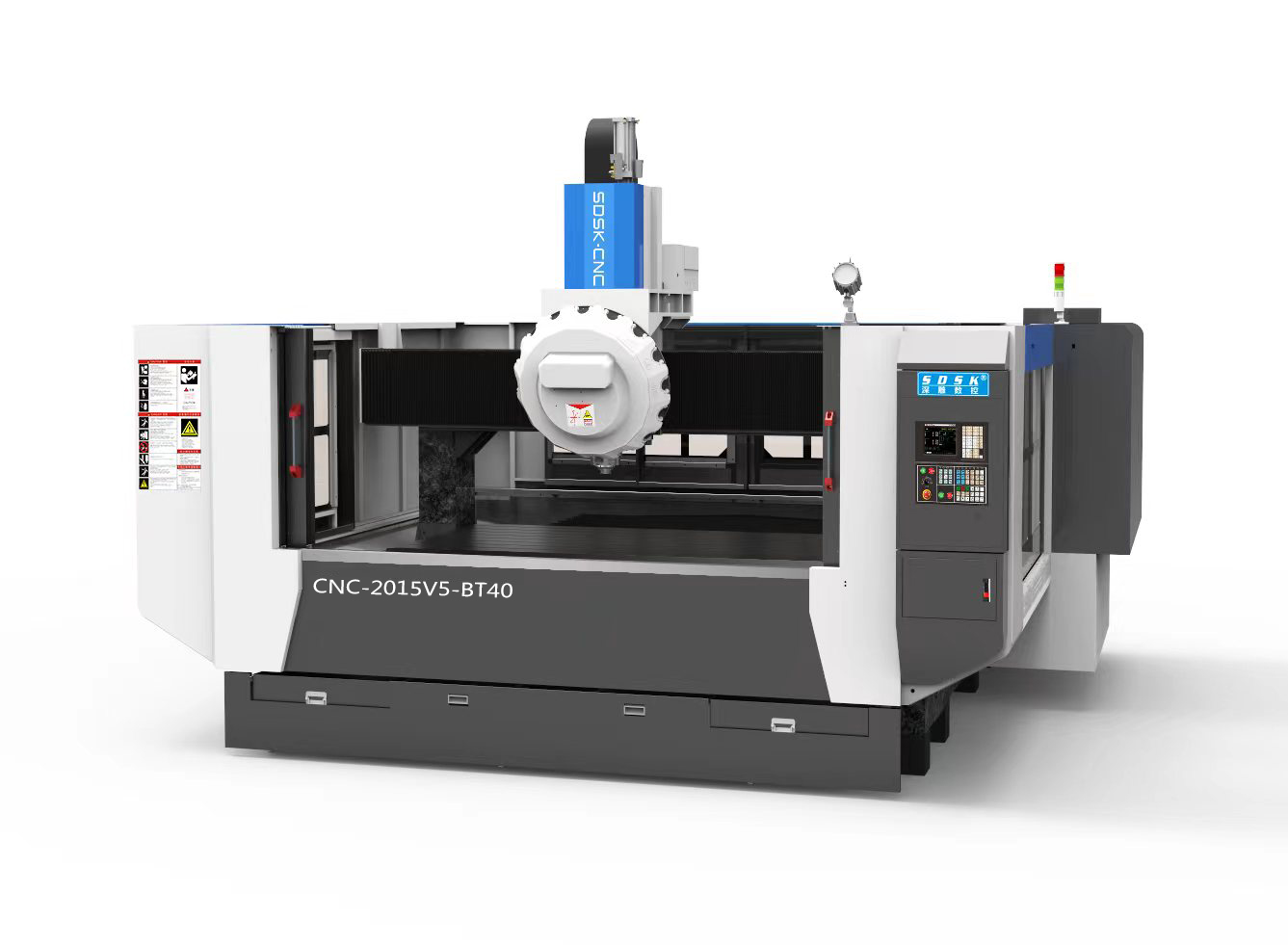

1. the sdsk2015v5-bt40 model is a lightweight 2-meter gantry machining center specially designed for customers; fixed beam structure; equipped with taiwan shengjie 16 bit ufo style knife magazine, with a tool changing speed of 2 seconds; the movement mode is to move the y-axis workbench forward and backward, the x-axis to move left and right, and the z-axis to move up and down< br/>

2. the body adopts a top-notch granite (marble) structure that never deforms; three axis adopts imported taiwan shangyin precision linear guide rail, taiwan tbi; grinding grade ball screw, german coupling, servo motor, distribution cabinet constant temperature system, advanced spindle cooling system, automatic lubrication system, water circulation cooling liquid spray system, air filtration device, ensuring higher processing accuracy, speed and stability; especially suitable for precision engraving, milling, cutting, expanding, punching, tapping and other processing of various types of steel, copper, aluminum, acrylic, plastic and other parts< br/>

3. additionally, a fourth rotary shaft, side milling head, and probe function can be added< br/>

& nbsp& nbsp< br/>

(the pictures are for reference only, subject to the actual product)

(the pictures are for reference only, subject to the actual product)

2、 list of main machine configuration (unit: mm)

number

regulations; grid; speak; bright

quantity

deep carving cnc system/3-axis 3kw huichuan servo motor, z-band brake/spindle servo drive 7.5-11kw

full set

taiwan dayue straight nose spindle bt40-150-560-12000/with cooling water outlet (equipped with hydraulic cutting cylinder)

full set

taiwan shengjie 16t ufo servo tool magazine

1 set

xyz axis using taiwan/intime/ & nbsp; precision linear guide;

full set

taiwan tbi for xyz axis; precision grade grinding ball screw

full set

outer cover: 2mm steel plate, baked paint (stainless steel water tank)

1 set

aluminum workbench size: 2000 in x direction, 1500 in y direction, thickness 50, with t-shaped groove

1 set

marble body, marble crossbeam

1 set

cast iron mechanical parts

1 batch

distribution cabinet constant temperature system

1 set

schneider electric accessories

1 batch

imported nsk/koyo/tbi& nbsp; p-grade angular contact paired bearings

full set

spindle oil cooler

1 unit

electronic handwheel

1 set

knife alignment instrument

1 unit

x/z-axis with three proof cloth organ cover (y-axis with retractable stainless steel plate cover)

1 set each

x/y/z axis plastic drag chain

1 set each

automatic lubrication oil pump

1 set

air filter

2 sets

water spray device

1 set

water pump 750w

1 set

machine tool accessories

1 set

bt40 knife handle/complete set of reduced nipple (three in one)

5

3、 main technical parameters of the equipment: (unit: mm)

model

sdsk2015v5-bt40

workbench size

2000 * 1500; (t-slot m14)

gantry width

two thousand and sixty

spindle nose end to workbench

max 670~min 170

flying saucer tool magazine to workbench

minimum 500

x-axis travel

two thousand and thirty

travel y-axis

one thousand five hundred and thirty

z-axis travel

five hundred

x/y/z fastest movement speed

x35 meters/minute

y40 meters/minute

z40 meters/minute

maximum processing speed

12 meters per minute

control system

deep carving cnc system

servo system

ac servo

system resolution

zero point zero zero one

three axis verticality

0.015mm

whole machine positioning accuracy

± 0.02mm

localization accuracy

within 300± 0.01mm

repetitive positioning accuracy

0.004mm

number of spindles

1 & nbsp;

spindle servo power

7.5-11kw

spindle servo torque

35.8n. m

spindle speed

12000 rpm/min

ufo type tool magazine

16 bit

knife changing method

automatic

clamping tool handle

bt40

knife alignment method

automatic

the countertop bears a load

1000kg

rated voltage

380v/50hz

maximum power of the entire machine

21kw

overall weight

about 10000kg

external dimensions (length * width * height)

approximately 3350 * 3900 * 3400

4、 standard configuration and accessories for the host:

one

controller

eleven

1 mechanical, electrical, and operation manual

two

straight spindle bt40-150-560-12000 long nose

twelve

rigid tapping function

three

automatic lubrication system

thirteen

electrical box heat exchanger

four

adjustable foundation cushion block

fourteen

1. the sdsk2015v5-bt40 model is a lightweight 2-meter gantry machining center specially designed for customers; fixed beam structure; equipped with taiwan shengjie 16 bit ufo style knife magazine, with a tool changing speed of 2 seconds; the movement mode is to move the y-axis workbench forward and backward, the x-axis to move left and right, and the z-axis to move up and down< br/>

2. the body adopts a top-notch granite (marble) structure that never deforms; three axis adopts imported taiwan shangyin precision linear guide rail, taiwan tbi; grinding grade ball screw, german coupling, servo motor, distribution cabinet constant temperature system, advanced spindle cooling system, automatic lubrication system, water circulation cooling liquid spray system, air filtration device, ensuring higher processing accuracy, speed and stability; especially suitable for precision engraving, milling, cutting, expanding, punching, tapping and other processing of various types of steel, copper, aluminum, acrylic, plastic and other parts< br/>

3. additionally, a fourth rotary shaft, side milling head, and probe function can be added< br/>

& nbsp& nbsp< br/>

(the pictures are for reference only, subject to the actual product)

(the pictures are for reference only, subject to the actual product)2、 list of main machine configuration (unit: mm)

number

regulations; grid; speak; bright

quantity

deep carving cnc system/3-axis 3kw huichuan servo motor, z-band brake/spindle servo drive 7.5-11kw

full set

taiwan dayue straight nose spindle bt40-150-560-12000/with cooling water outlet (equipped with hydraulic cutting cylinder)

full set

taiwan shengjie 16t ufo servo tool magazine

1 set

xyz axis using taiwan/intime/ & nbsp; precision linear guide;

full set

taiwan tbi for xyz axis; precision grade grinding ball screw

full set

outer cover: 2mm steel plate, baked paint (stainless steel water tank)

1 set

aluminum workbench size: 2000 in x direction, 1500 in y direction, thickness 50, with t-shaped groove

1 set

marble body, marble crossbeam

1 set

cast iron mechanical parts

1 batch

distribution cabinet constant temperature system

1 set

schneider electric accessories

1 batch

imported nsk/koyo/tbi& nbsp; p-grade angular contact paired bearings

full set

spindle oil cooler

1 unit

electronic handwheel

1 set

knife alignment instrument

1 unit

x/z-axis with three proof cloth organ cover (y-axis with retractable stainless steel plate cover)

1 set each

x/y/z axis plastic drag chain

1 set each

automatic lubrication oil pump

1 set

air filter

2 sets

water spray device

1 set

water pump 750w

1 set

machine tool accessories

1 set

bt40 knife handle/complete set of reduced nipple (three in one)

5

3、 main technical parameters of the equipment: (unit: mm)

model

sdsk2015v5-bt40

workbench size

2000 * 1500; (t-slot m14)

gantry width

two thousand and sixty

spindle nose end to workbench

max 670~min 170

flying saucer tool magazine to workbench

minimum 500

x-axis travel

two thousand and thirty

travel y-axis

one thousand five hundred and thirty

z-axis travel

five hundred

x/y/z fastest movement speed

x35 meters/minute

y40 meters/minute

z40 meters/minute

maximum processing speed

12 meters per minute

control system

deep carving cnc system

servo system

ac servo

system resolution

zero point zero zero one

three axis verticality

0.015mm

whole machine positioning accuracy

± 0.02mm

localization accuracy

within 300± 0.01mm

repetitive positioning accuracy

0.004mm

number of spindles

1 & nbsp;

spindle servo power

7.5-11kw

spindle servo torque

35.8n. m

spindle speed

12000 rpm/min

ufo type tool magazine

16 bit

knife changing method

automatic

clamping tool handle

bt40

knife alignment method

automatic

the countertop bears a load

1000kg

rated voltage

380v/50hz

maximum power of the entire machine

21kw

overall weight

about 10000kg

external dimensions (length * width * height)

approximately 3350 * 3900 * 3400

4、 standard configuration and accessories for the host:

one

controller

eleven

1 mechanical, electrical, and operation manual

two

straight spindle bt40-150-560-12000 long nose

twelve

rigid tapping function

three

automatic lubrication system

thirteen

electrical box heat exchanger

four

adjustable foundation cushion block

fourteen