due to the three-dimensional characteristics of processing steel pipe materials, the control system design and operating principles of aluminum profile cutting machines are still different. currently, among several major domestic product brands

due to the three-dimensional characteristics of processing steel pipe materials, the control system design and operating principles of aluminum profile cutting machines are still different. currently, among several major domestic product brands, the entire processing process is mostly implemented by combining intersecting line components and cutting torch components. among them, the intersecting line digital control cutting machine mainly provides clamping and rotation of the steel pipe, and the cutting operation is carried out by the cutting torch part. so what is the operating principle of the aluminum profile cutting machine? what are its advantages reflected in< br/>

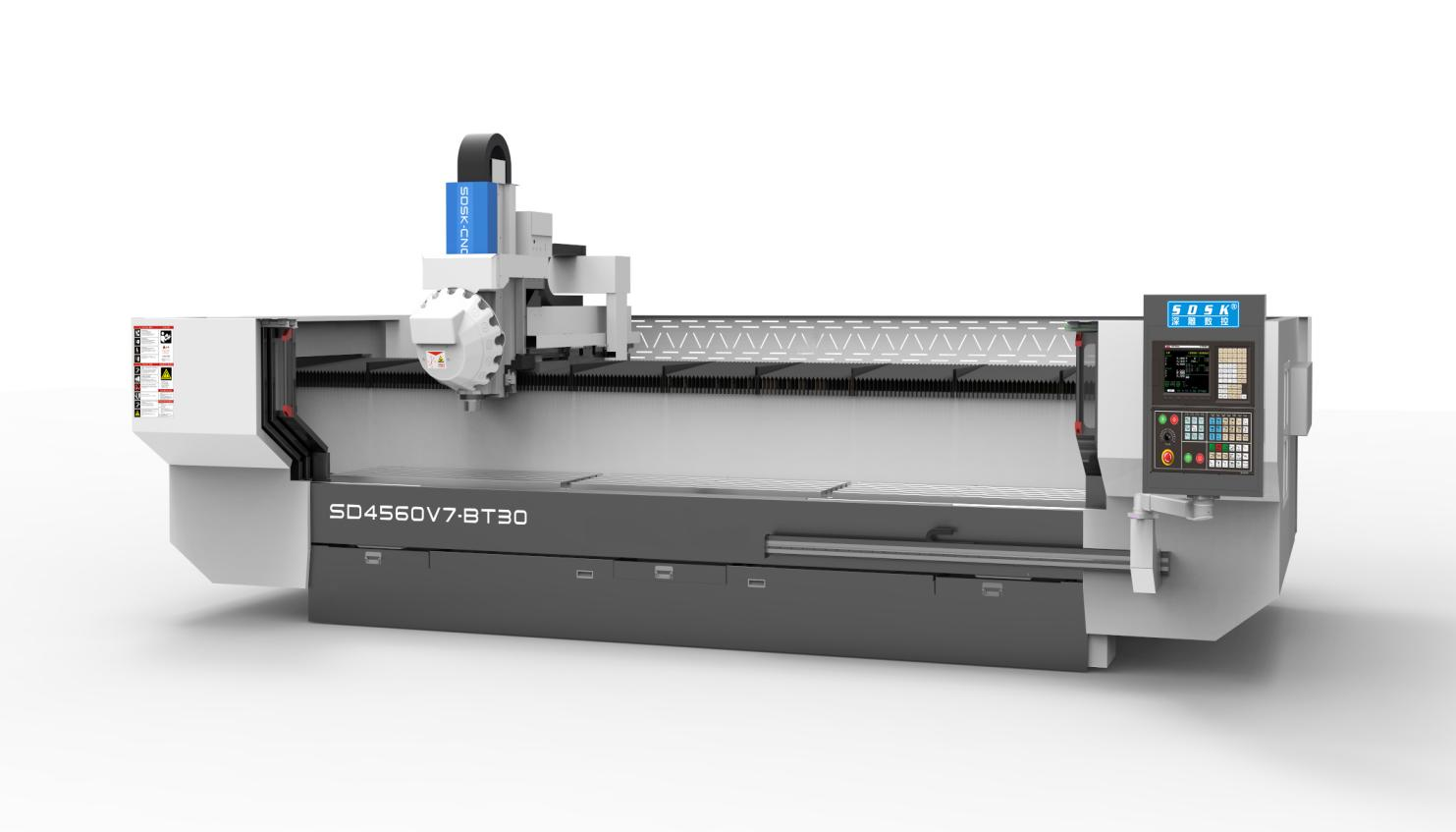

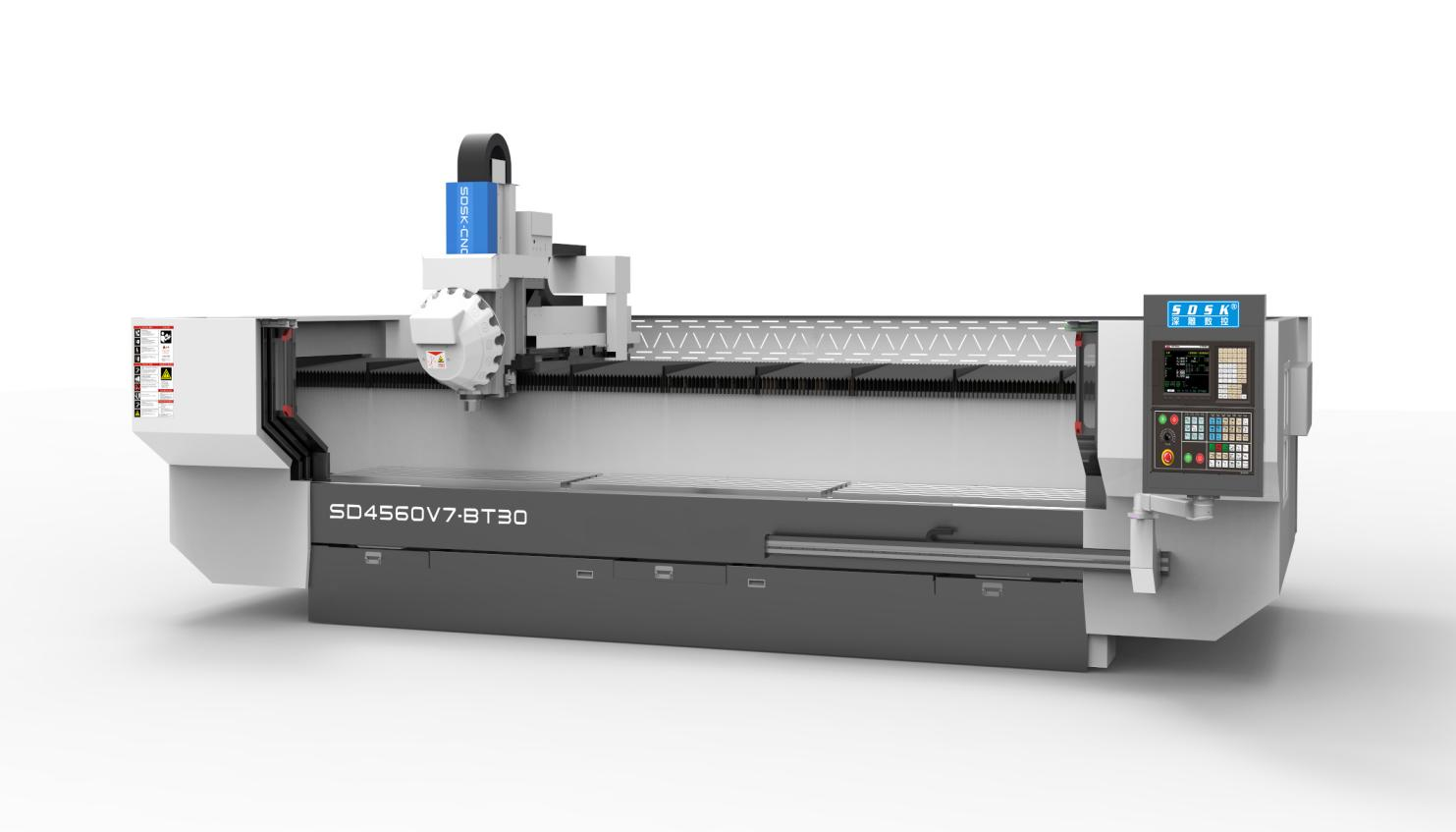

the so-called aluminum profile cutting machine equipment refers to a special type of cnc cutting machine equipment that cuts and processes three-dimensional materials such as steel pipes. compared to cutting flat materials such as steel plates, the processing of aluminum profile cutting machines is more unique. the cnc aluminum profile cutting machine products have been developed and applied, with two axis function, three axis function, four axis function, five axis function, and even six axis function. once launched, the aluminum profile cutting machine has been widely used in the market and has received praise. it is widely used in the steel structure industry, shipbuilding industry, military enterprises, petroleum, water and electricity pipelines, engineering machinery, automobile manufacturing, etc! driven the trend of automatic cutting of steel pipe cnc cutting machines,

1. able to cut and weld elbows on circular pipes; shrimp festival; diagonal cross-section at both ends< br/>

2. able to cut the end of the intersecting line with the circular main pipe< br/>

3. able to cut the end of the intersecting line of the cylinder at the end of the branch pipe, meeting the conditions of vertical and oblique intersection between the branch pipe axis and the main pipe axis, both eccentric and non eccentric< br/>

4. able to cut oblique end faces at the end of circular pipes< br/>

5. able to cut off steel pipes& nbsp& nbsp& nbsp; 6. able to cut square holes and waist shaped holes on circular pipes< br/>

7. able to cut multiple intersecting cylindrical holes with different directions and diameters on the main pipe, meeting the conditions of eccentric and non eccentric vertical intersection between the branch pipe axis and the main pipe axis.